This week's focus was to perform a shakedown test on the functionality of the disk and gather equations that will lead to improvements to the design.

Shakedown Test Video:

Shakedown Test Description and Calculations

The disk is placed over a motorized rotating shaft that requires 0.28 amps to rotate the disk. During the shakedown test it was recorded that for the disk to complete one revolution, it required 6.3 seconds. Therefore, the following calculation can be made:

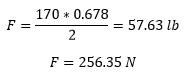

When the pressure applied with the upper body of a 170-pound person on the disk, the following calculations can be made:

- Actual force applied to the disk:

- - If the radius of the disk is 0.0889, the cross-sectional area of the disk is calculated as follows:

- With the surface area of the disk being 0.02484 m^2, the pressure applied to the disk is as follows:

When the disk is rotating without any pressure applied, the current required to rotate the disk is 0.28 amps, however, when the pressure is applied to the disk the current required to rotate the disk is 0.5 amps. Also, the voltage is a constant of 23.7 volts. Therefore the following equations can be made:

Therefore, the power increase is calculated by the following equation:

The maximum power output for the motor is 30 watts. While we used only 39.5 % of the maximum power output of the motor is can be concluded that a motor with half that power would be sufficient to use for our design.

From the shakedown test, it was observed that all the markers spread out within a fluidized bag, were relocated towards the center of the disk within 47 seconds of disk rotation.

Therefore the following equation can be made:

From a common wheelchair battery of 12v 35 aH, can make the following calculation of how much energy is contained within the battery:

If we plan on running the loaded disc for 1 minute each thirty minutes, this consumes 711 Joules each cycle.

Since this happens 2 times per hour for 16 hours, each day is consumes 22752 Joules

Therefore we can say that each day our device consumes less than 2% of the wheelchair’s total battery life.

Brainstorming Session from October 30, 2017:

From this brainstorming session, we determined three different designs from which the group will agree to work further based on the results of the shakedown test.

The first design (left) is a design that simulates a movable hammock type of seat that will be mechanically moved in order to alternatively distribute the weight of the wheelchair user to prevent ulcers.

The second concept design (middle) is a design that is based on a disk with a void in the middle, which will leave the most concentrated pressure points from having minimum contact to the disk as possible while the rest will be massaged by the disk to distribute the blood circulation towards the such pressure points.

The third desgin, deals with the same concept as the second one, however, it leaves an extra void at the bottom to not cause constant pressure on the legs. This design will work with rollers that will be pushed up by a wedge which will cause blood circulation towards such pressure points.